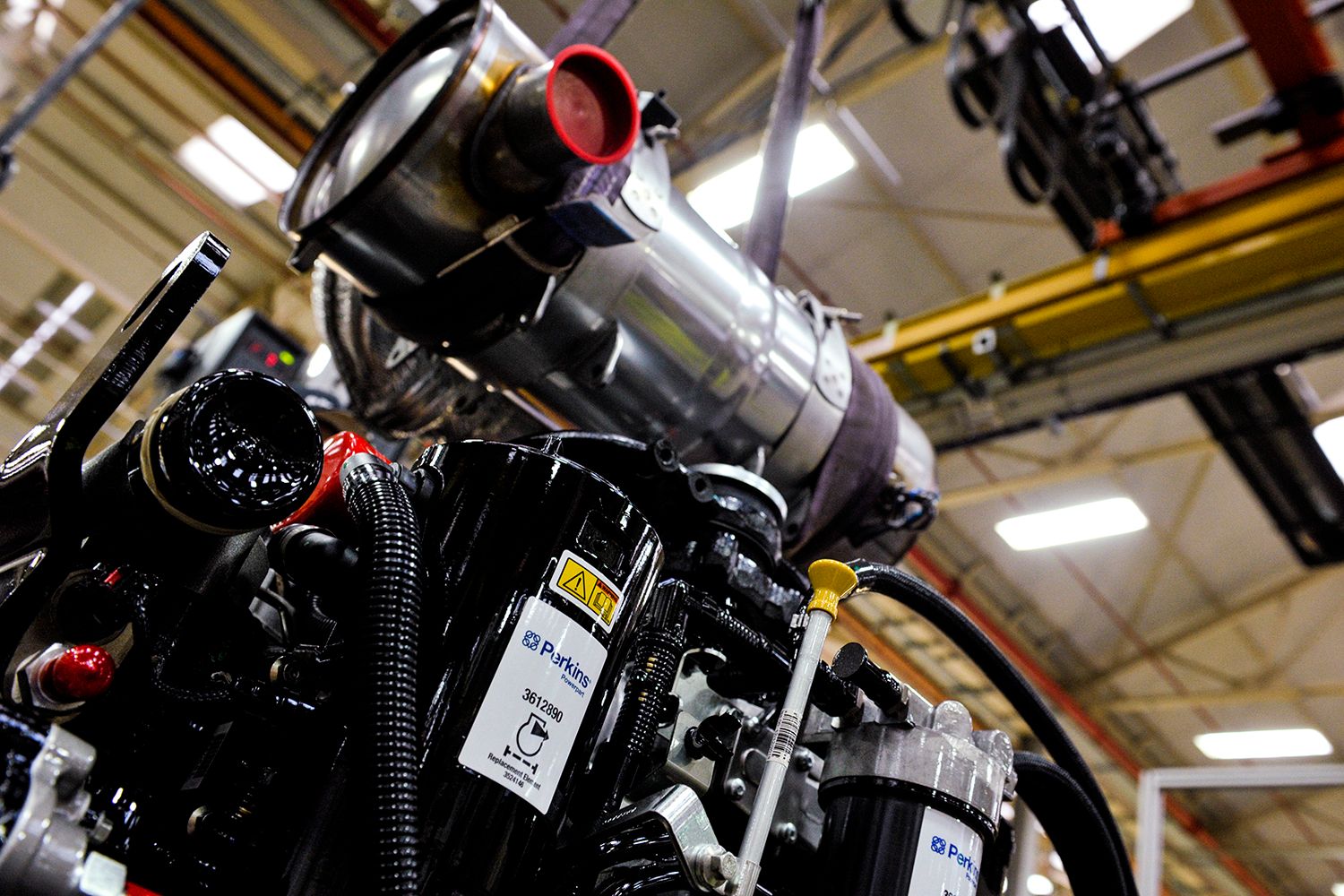

Sustainability

Perkins is committed to sustainable manufacturing. We promote continual improvement and are focused in driving reductions in three key areas; waste, water and energy. Sustainability is key to a successful business and is at the forefront of our minds in relation to products as well as in our global facilities.

Sustainability is a core value for our business. At each one of our facilities, we’re focused on:

- Driving out wastage

- Operating an efficient and cost-effective system that uses as minimal energy as possible

- Minimising emissions

- Recycling/reusing waste products where possible in line with the waste hierarchy

Robotic and computerised production lines

Robotic and computerised production lines

Automation of heating, lighting, compressed air and cooling systems

All substances re-used and recycled